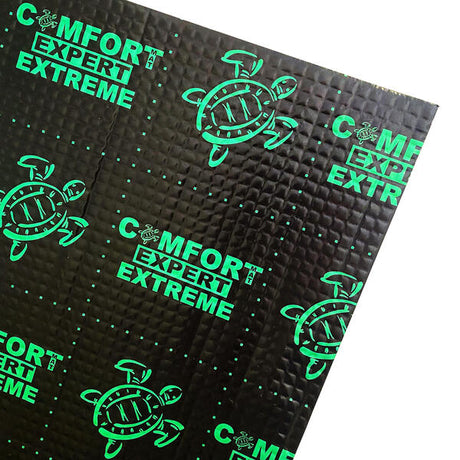

Vibration isolation.

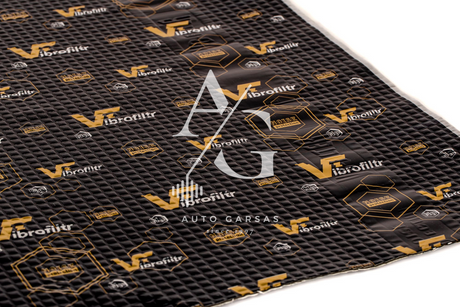

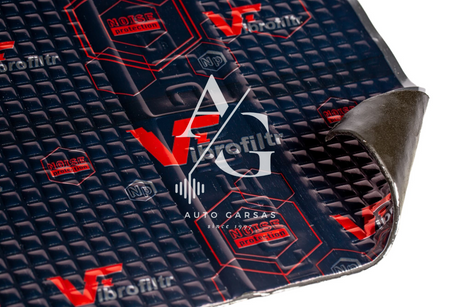

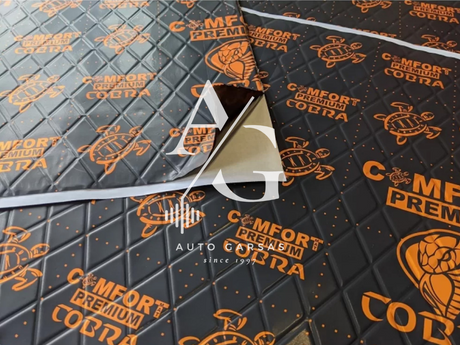

Vibration isolation, its purpose is to suppress resonances of flat surfaces (the so-called drum effect). For this, vibration isolation is most often used - bitumen mastic with various additives, so that at sub-zero ambient temperatures this material does not harden and cease to function. This is very important when choosing vibration isolation. Bitumen sheets from cheap manufacturers - vibration isolation material - harden into stone in winter and do not perform their function, even worse, when they crack and fall apart from vibration. The car audio salon and website www.autogarsas.lt offer you high-quality vibration isolation materials.

How does it work? Metal, plastic, bitumen and aluminum materials have different resonant frequencies. Therefore, when these materials are glued one on top of the other, they dampen each other, which results in the desired effect. The greater the thickness or number of layers of such materials, the greater the damping effect, but it should be remembered that these materials are not light, so the weight of the car parts also increases rapidly. So if you are going to glue the trunk lid - vibration isolation material for a car - consider that the gas shock absorbers of the lid will have to overcome all the additional weight so that it does not fall down on its own.

Vibration isolation, the materials used for it thicken vibrating surfaces. Most often, it is a mixture of bitumen with additives coated with an aluminum layer. When such a material is glued to a vibrating surface, the resonant frequencies of bitumen and aluminum are different, so the vibration is damped as effectively as possible. It is recommended not to buy the cheapest and unknown manufacturers, simply because such products usually harden at sub-zero temperatures and do not perform their function.

Vibration isolation is the process of reducing or eliminating the transmission of vibration from one surface to another. This is often achieved by using specialized vibration isolation materials that can absorb, dampen, or otherwise control vibration.

There are various reasons why vibration isolation may be required. In some cases, it may be to protect sensitive equipment from damage caused by excessive vibration. In other cases, it may be to reduce noise levels or improve the comfort of building occupants.

Vibration isolation can be important in a variety of applications, from industrial machinery and construction equipment to sensitive laboratory equipment and even in homes and buildings. Reducing vibration transmission can help protect equipment, improve safety and create a more comfortable environment for occupants.

Vibration isolation material - vibroisolation - is an essential component of a modern car and is used to reduce the transmission of vibrations from the engine, transmission and road surface into the interior of the car. Vibroisolation material is designed to absorb, dampen or redirect vibrations, ensuring a smoother and more comfortable ride for passengers.

One of the most commonly used vibration isolation materials in automobiles is rubber. This vibration isolation is widely used to manufacture engine mounts, suspension bushings, and other components. Rubber is an effective vibration isolator due to its ability to absorb and dissipate energy, thereby reducing the transmission of vibrations.

Another material used for vibration isolation in cars - vibro isolation for cars - is foam. This material is used for various applications, such as door panels, upholstery and seats. Foam effectively reduces vibrations due to its ability to compress and absorb energy.

Besides rubber and foam, other vibration isolation materials commonly used for vibration isolation in automobiles are steel springs, fiberglass, and cork. Steel springs are used in suspension systems to absorb shock and vibrations. Fiberglass is used for soundproofing because it can absorb and reflect sound waves. Due to its compressibility and ability to absorb vibrations, cork is used for a variety of applications, including gaskets and seals.

Advanced automotive vibration isolation materials such as carbon fiber and Kevlar are increasingly being used in high-end cars because they are extremely strong and resistant to vibration. These materials are also lightweight, which can help improve fuel efficiency and handling.

Overall, vibration-isolating vibration isolation is an essential component of modern car design and plays a crucial role in ensuring a smooth and comfortable ride for passengers. Car manufacturers continue to research new vibration isolation material technologies to improve vibration isolation and create even more comfortable and sophisticated vehicles.

For vibration isolation and its installation in your car or other room, contact the consultants of the Autogarsas salon or you can find vibration isolation material on the www.autogarsas.lt website.